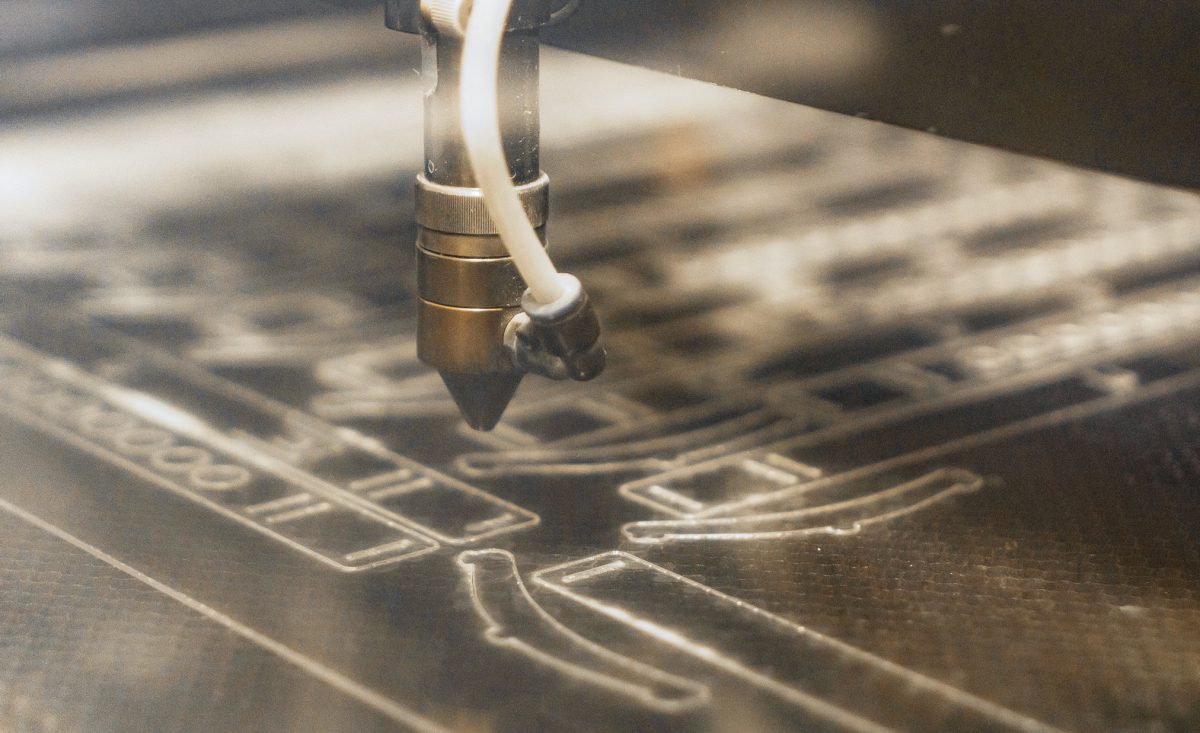

As campus closures remain in effect due to the COVID-19 pandemic, students and faculty continue to face the challenges that accompany virtual learning. City College’s Makerspace has been shut down as well, leaving Maker majors without equipment and faculty guidance to complete tactile projects, hone their skills and make valuable connections in a safe environment.

Employing their skills as needleworkers and expert craftsmen, some Makers have made cloth masks.

“I have my 87-year-old mother sewing face masks at home in isolation with patterns you can download online. It’s not medical, but in a smoky fire, a wet bandana works,” said Tom Cappelletti, Makerspace faculty project director. “They’re going to be in demand for the next few months.”

But some Makerspace students are embarking on a project to answer the current need for personal protective equipment, or PPE. Cappelletti told students in an April 3 memo that the roughly $7,500 in Makerspace supply funds would be used to buy materials to manufacture face shields and other protective equipment for healthcare professionals in the region.

“By now, though, we’ve pretty much spent all that money,” Cappelletti said. “Most of it went towards the clear plastic for the face shields. We also ordered the filament for the 3D printers. It looks like we’ll be able to make about 2,000 masks now that we have supplies all set.”

The restrictions brought on by the ongoing pandemic also mean that, in order to complete a project of this scope, some of City College’s equipment has been moved off campus. Cappelletti’s memo also detailed a solution to this problem: scheduling shifts at Hacker Lab, located in downtown Sacramento.

Lab techs and instructional assistants from Makerspace are volunteering to help off campus, according to Cappelletti.

“Hacker Lab has very stringent social distancing ordinances. The volunteers have begun the process of cutting the clear plastic,” Cappelletti said. “We have about 15 to 20 students and staff who’ll probably come two or three at a time on shifts.”

According to Eric Ullrich, one of three Hacker Lab co-founders, some of their members have already been creating shields over the last few weeks. Hacker Lab has been working with Makerspace since last June.

“However, we’ve been working together with them as a part of the California Community College Maker Initiative through our work with Sierra College, which began in 2016,” said Ullrich.“The Sacramento location got set up in late 2012. It just moved to 29th Street and R, and we really upgraded. That’s where Sac City students can have full access if they’re a part of the [City College] Makerspace program, at no additional charge.”

Hacker Lab has two other locations—one in Rocklin, open since 2015, and a satellite location opened in Rancho Cordova in 2018, according to Ullrich.

While testing prototype designs of the face shields, City College makers have had a wealth of resources in the online maker community.

“This began with us trying to make our own ventilators, which is way over our heads. We could make tiny components, but major industry covered that. It became PPE from there,” said Cappelletti describing the evolution of the idea for the project.

Cappelletti explained that through collaborative efforts, makers from all over have created a prototype that can be efficiently produced. Ideas and suggestions came not only from City College students, but the maker community online.

“One design came from the Czeck Republic and another from the University of Wisconsin. Some of the shields are on their fourth, fifth and sixth version,” Cappelletti said excitedly. “Eventually it becomes like a mixtape and it’s owned by everyone. Everything’s in a creative commons. It’s a beautiful thing to see.”

According to Cappelletti, 3D printers are not meant to be used for the kind of production that is required to expedite creation of these shields.

“They’re more of a design tool. We’re probably going to be using it to create the ear protector pieces,” Cappelletti said, noting that it can take two to three hours per piece. “That’s fine, though. We’ll make hundreds of those. We got permission and moved five of the printers with that capability to Hacker Lab in midtown for this project.”

To distribute completed face shields, City College Makerspace volunteers are partnering with the Operation Shields Up. The items created at Hacker Lab by students and staff of Makerspace will be donated to this effort.

“They’re about $1 each, if you order them in a higher quantity,” Cappelletti said. “There’s already a pipeline to get these to various facilities. All kinds of places like homeless shelters, food bank lines and elder facilities have made requests for these masks.”

Hacker Lab is designed to provide tools and space for individuals and group projects much like this effort from City College makers. Both the Rocklin and Sacramento locations are 15,000 square feet, and the Rancho Cordova space is only about 1,500. Ullrich gave his assurance that makers working in Hacker Lab locations should have the proper amount of safe space in which to work.

Cappelletti speaks of the students he interacts with through Makerspace and the online communities, describing the shared connections with enthusiasm.

“There’s a spirit of people that don’t want to just be consumers, they want to tinker and build,” Cappelletti said. “Maker is definitely a thing. It’s kinda like this culture combination of DIY and upcycling and recycling. It’s refreshing to see in America. It’s the true spirit of inventors and tinkerers.”

According to Cappelletti, the notion of ownership over ideas is not something that’s a priority in the maker community. There’s more of a drive to create efficient and innovative designs and to do so collaboratively.

“The silver lining to me for my students is that this is something that everyone will remember for the rest of their lives,” Cappelletti said. “They’ll remember how people stepped up and helped out. This project shows me the power of building community even when we’re isolated.”